How Hydrogen Fuel Cells Work

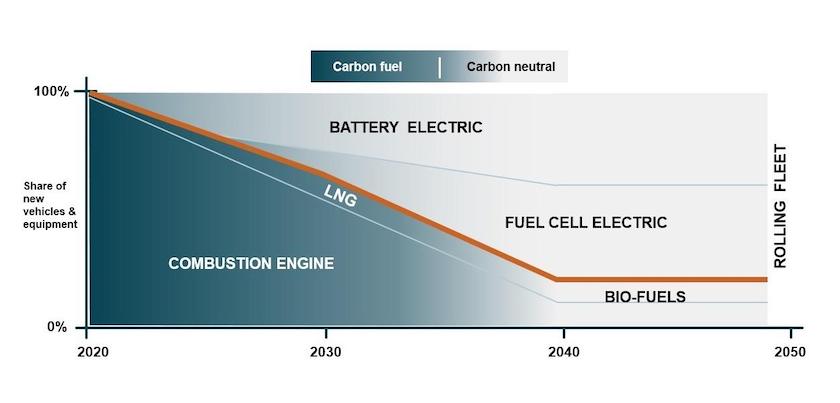

While battery electric solutions are ideal for smaller machines in urban construction, landscaping and many other applications, the size and weight of the batteries may not be practical for larger machines at […]

While battery electric solutions are ideal for smaller machines in urban construction, landscaping and many other applications, the size and weight of the batteries may not be practical for larger machines at this time. This is where hydrogen comes in as a promising alternative.

If you aren’t familiar with how hydrogen fuel cell technology works — or you just need a brush up — this article explains the technology so you can better understand what we’re currently working on here at Volvo CE and within the broader Volvo Group to help drive change toward a future of net-zero emissions.

HOW DO HYDROGEN FUEL CELLS WORK?

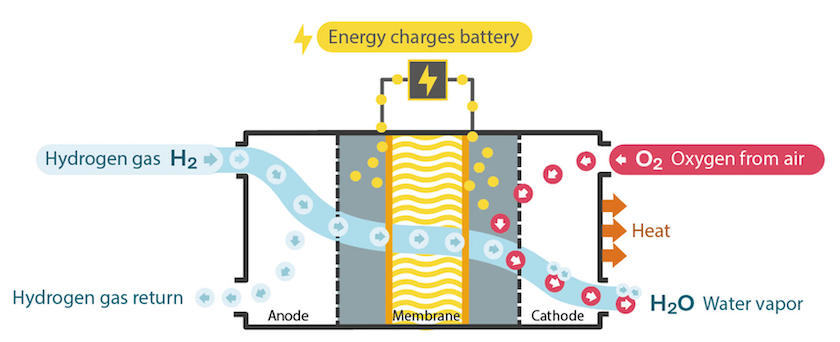

Simply put, fuel cells work by combining hydrogen gas (H2) with oxygen from the air — and the resulting chemical reaction produces electricity. Here’s how it works:

- Hydrogen atoms enter the fuel cell at the anode, while oxygen is fed to the cathode.

- The fuel cell consists of a membrane coated with a catalyst. When the hydrogen molecules hit the catalyst, they’re split into hydrogen ions and electrons.

- The membrane lets positively charged hydrogen ions pass through, but not the negatively charged electrons, which instead flow through an electric circuit where the electric current is generated.

- At the cathode side, the hydrogen ions, electrons and the oxygen in the air combine to produce heat and

- In order to produce enough electricity to be able to propel a vehicle, a complete fuel cell system consists of several hundred membranes stacked together.

- The fuel cell system is adequate for normal use, but whenever extra power is needed, it’s provided by a battery on the machine. When the fuel cells produce more power than the machine currently needs, the excess energy can be used to charge the battery. The battery is also charged by regenerative braking.

- A control unit balances the dynamics between the fuel cells and the battery to optimize the use of energy. Through this process, we can provide the same operational range and load capacity as a machine with a diesel engine, but with zero Green House Gas (GHG) emissions.

So in principle, a fuel cell works much like a battery, except that it generates its own electricity from the hydrogen onboard rather than being charged from an external source. Fuel cells also won’t run down or need recharging as long as the fuel source (hydrogen) is supplied. Again, this means they can deliver longer driving ranges, and therefore are more feasible for long-haul transportation and for powering heavier construction equipment.

An added benefit of hydrogen fuel cell technology is that, without an internal combustion engine, hydrogen-powered machines will be comparable to the low noise levels of electric machines.

OUR COMMITMENT TO DEVELOPING CLEAN HYDROGEN FUEL CELL TECHNOLOGY

In 2021, Volvo Group officially launched cellcentric, a joint venture with Daimler Truck, with the goal of becoming a leading global manufacturer of hydrogen fuel cells. When green hydrogen based on renewable energy is used, fuel cell machines can reduce carbon emissions to zero. Hydrogen can also offer a path to reduce CO2 emissions with a minimal grid investment (expanding hydrogen infrastructure) and by then offering an opportunity to quickly scale zero emission vehicles and machines.

Our recently launched Fuel Cell Test Lab is a demonstration of the same dedication to hydrogen fuel cell technology to accelerate the development, production, storage and commercialization of fuel cell solutions within long-haul trucking and construction equipment.

As an example, we recently started testing the world’s first fuel cell powered articulated hauler prototype, the Volvo HX04. The results of the project will provide important insights into the possibilities provided by hydrogen and fuel cells as we continue research for future product development programs.

We also note that hydrogen can be produced in many different ways, so it’s critical to have a lifecycle approach across the entire value chain. Not only will the research and development carried out at our test lab be dedicated to producing fossil-free construction solutions, but we’ll also look at how the hydrogen itself has been produced, and strive for green hydrogen produced from renewable energy.

All of this is a part of Volvo Group’s overall ambition to be 100% fossil free by 2040 — and as a part of Volvo Group, it’s our mission here at Volvo CE too.

Want to get involved? Learn more about our CO₂ Reduction Program to discover ways to reduce your own carbon footprint.

Categories: Construction Equipment, Fuel Consumption, Insights